Are you looking for a sustainable way to produce fuel? Wood pellet machines can be your solution. They are the perfect equipment to convert waste wood and biomass into pellets. These pellets are an eco-friendly way of producing energy.

This comprehensive guide will cover everything you need to know about wood pellet machines. We will explain how they work and what types of machines are available in the market. You will also learn about different wood pellet plants’ capacity and functionality.

The guide also includes information about biomass processing machines and tips on choosing the right wood pellet mill manufacturers. Lastly, we have included a step-by-step guide on making wood pellets from sawdust and handling issues with wood pellet machines.

Read on to discover all you need to know about producing sustainable energy with a wood pellet machine.

What is a Wood Pellet Machine?

A wood pellet machine is a device that transforms biomass materials into pellets for heating or energy generation. With different sizes and capacities, these machines compress and shape raw materials using pressure and heat.

Different Types of Wood Pellet Machines

Wood pellet machines come in various types, including pelletizer machines and pellet-making machines. Different models are available, such as feed pellet machines and pellet mills. Some wood pellet machines use rollers, while others utilize a ring die pellet mill.

Diesel and electric options are available, catering to different needs. Wood pellet machines can efficiently produce biomass pellets for various applications.

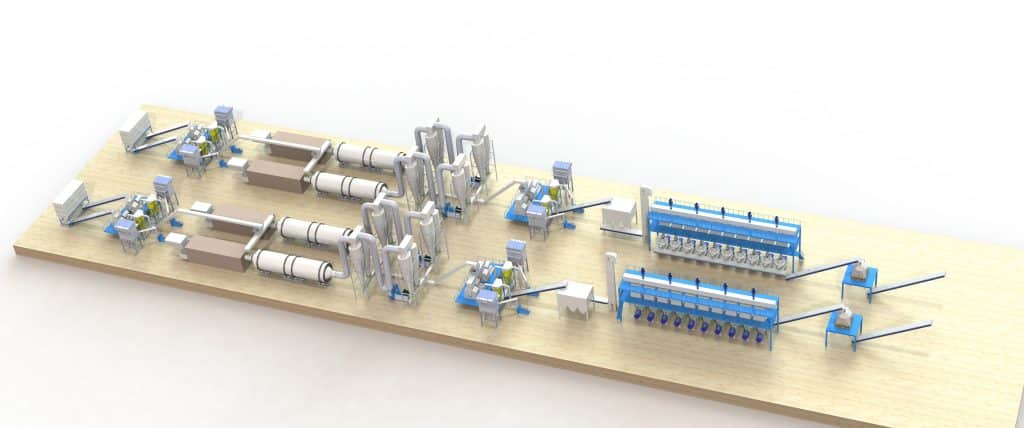

Detailed Explanation of Various Wood Pellet Plants

The 4-5T/H wood pellet plant is suitable for large-scale production, while the 400-600kg/h mobile wood pellet line offers flexibility and easy transportation. The 100-350kg/h wood pellet plant is best for small-scale production or home use.

Depending on raw material availability and desired production output, these plants utilize machinery such as hammer mills and dryers.

4-5T/H Wood Pellet Plant

The 4-5T/H wood pellet plant is designed for large-scale production, incorporating a ring die pellet mill for efficient pelletizing. It can process various biomass materials like sawdust and rice husk, ensuring the desired moisture content for optimal pellet quality. This plant offers a renewable energy solution for industries.

400-600kg/h Mobile Wood Pellet Line

The 400-600kg/h mobile wood pellet line offers flexibility and mobility, making it suitable for on-site pellet production or locations with limited space. This mobile line comprises a wood pellet machine, dryer, and other necessary equipment.

The pellets’ diameter can be customized based on requirements, making it the best choice for small-scale operations and ensuring optimal pellet production.

100-350kg/h Wood Pellet Plant

The 100-350kg/h wood pellet plant is compact and designed for home or small-scale production. It utilizes a flat die pellet mill for efficient pellet production. This plant processes biomass materials like sawdust, alfalfa, and rice husk.

The moisture content of the raw material affects pellet quality and combustion efficiency. It offers an eco-friendly alternative for heating or animal bedding.

Understanding Wood Pellet Mills

Wood pellet mills are vital for converting biomass materials into pellets. Vertical ring die wood pellet mills are known for their efficiency and capacity, while industrial-use ring die mills are designed for large-scale production.

Electric flat die mills suit home use or small-scale production, while diesel flat die mills offer flexibility in areas without an electricity supply.

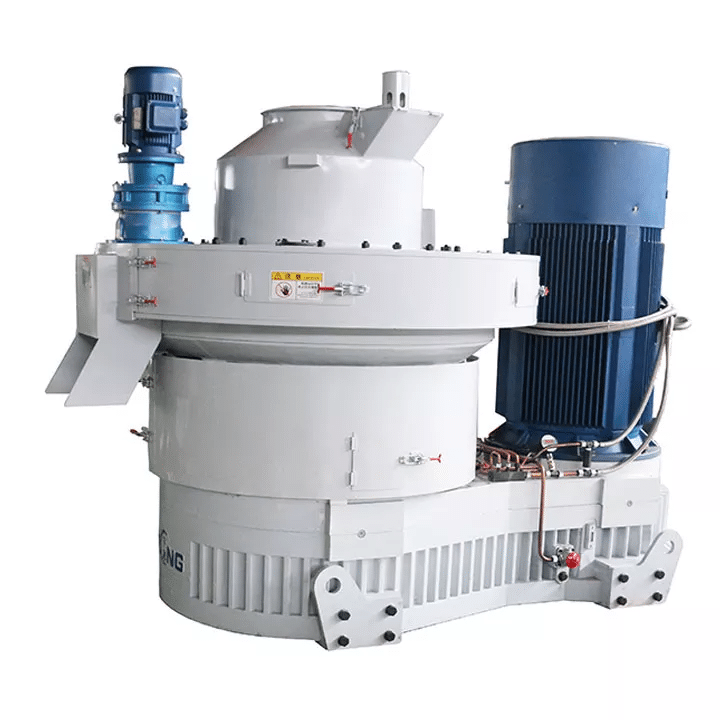

Vertical Ring Die Wood Pellet Mill

Vertical ring dies wood pellet mills are the best for large-scale production. With a vertically rotating ring die, these mills reduce wear and offer a longer machine lifespan. They produce high-quality wood pellets with consistent density and durability.

Widely used in commercial pellet plants, raw materials are compressed and pelletized vertically.

Industrial-use Ring Die Wood Pellet Mill

Industrial-use ring die wood pellet mills are designed for efficient high-capacity pellet production. They can process various biomass materials, including wood pellets and agricultural residues.

These mills utilize a horizontal ring die and multiple rollers for optimal pelletization. Reliable power sources and regular maintenance are necessary for their operation. They are commonly used in large-scale biomass pellet production facilities.

Electric Flat Die Wood Pellet Mill

Electric flat die wood pellet mills are compact and lightweight, making them suitable for home use or small-scale production. These mills are easy to operate with a flat die and stationary rollers. Electric motors power the pelletization process, offering convenience and affordability for producing biomass pellets.

Diesel Flat Die Wood Pellet Mill

Diesel flat die wood pellet mills are a versatile and convenient option for areas without electricity supply. Their flat die and rollers can efficiently process various biomass materials, including wood chips and agricultural wastes.

Powered by diesel engines, these mills offer mobility and flexibility, making them ideal for remote locations or mobile pellet production.

Biomass Processing Machines: An Overview

Wood pellet machines are crucial in biomass processing, converting biomass into pellets. They play a key role in efficient biomass utilization and are used for producing animal feed. Pellet mills are essential equipment in biomass pellet production, offering a variety of options such as small pellet mills and pto pellet mills.

Wood Hammer Mill and its Uses

Wood hammer mills are crucial for reducing the size of raw materials in biomass pellet production. These versatile machines process wood materials into smaller particles, affecting the quality of the final pellets. Used in various industries, they are vital in creating high-quality biomass pellets.

The Functionality of Wood/Log Debarker Machine

Wood/log debarker machines play a crucial role in the pellet production process by removing the bark from wood logs. This essential step improves the efficiency and quality of the pellets. These machines are designed to handle different sizes and types of wood, making them the best choice for biomass processing.

The Need for a Rotary Wood Dryer in Pellet Production

Proper drying of wood is crucial for the pelletizing process. Rotary wood dryers are used to reduce the moisture content of wood materials, improving the efficiency of pellet production.

This ensures low moisture content in wood, resulting in high-quality and durable pellets. These dryers are available in different sizes and capacities.

Utilization of Wood Shavings Machine

Wood shavings machines are highly versatile and capable of processing various wood materials. They produce wood shavings that serve as ideal animal bedding due to their absorbency and comfort.

Being efficient and cost-effective, these machines are popular for wood processing. The wood shavings they produce can be used for multiple applications.

Significance of Wood Crusher and Wood Chipper Shredder in Pellet Production

Wood crushers and wood chipper shredders play a crucial role in pellet production by reducing the size of wood materials. These machines ensure uniform particle size, resulting in higher-quality pellets. With various sizes and designs available, they are the best choice for efficient crushing and shredding in pellet production.

Tips on Choosing the Right Wood Pellet Mill Manufacturers

Consider the reputation and experience of manufacturers in biomass pellet production. Evaluate the quality, performance, after-sales service, and support provided by manufacturers. Compare prices and warranty terms offered by different wood pellet mill manufacturers. Choose the best manufacturer for a reliable and efficient wood pellet mill.

A Step-by-step Guide on How to Make Wood Pellets from Sawdust

To make wood pellets from sawdust, start by collecting the sawdust from woodworking processes or purchasing it from suppliers. Next, dry the sawdust to reduce its moisture content. Then, process the dry sawdust using a wood pellet machine, adjusting the settings for the desired pellet size and density. Finally, store the produced wood pellets in a dry and ventilated area.

How to Handle Issues with Wood Pellet Machines?

Dealing with problems in wood pellet machines? Regularly inspect and maintain the equipment to prevent issues. Follow the manufacturer’s guidelines for operation and troubleshoot common problems like blockages or uneven pellet production. Seek professional help for complex issues and keep spare parts on hand for quick repairs.

Conclusion

To conclude, a wood pellet machine is essential for converting wood waste into fuel pellets. Different types of wood pellet machines are available, each with unique features and capabilities.

Understanding the various wood pellet plants and mills can help you make an informed decision when choosing the right equipment for your needs. Additionally, biomass processing machines like wood hammer mills, log debarking machines, and wood chippers play a crucial role in pellet production.

When selecting a wood pellet mill manufacturer, consider factors such as reputation, quality, and customer reviews. Lastly, a step-by-step guide on making wood pellets from sawdust can serve as a helpful resource for beginners.

If you encounter any issues with your wood pellet machine, it’s important to address them promptly to ensure efficient and effective operation.