In the world of renewable energy and sustainable practices, biomass pellets have emerged as a promising solution. These compact, energy-dense pellets are made from organic materials like wood, agricultural residues, and even certain types of waste. One key player in the process of producing biomass pellets is the small wood chipper. In this article, we will delve into the significance of small wood chippers in biomass pellet production.

The Role of Small Wood Chippers

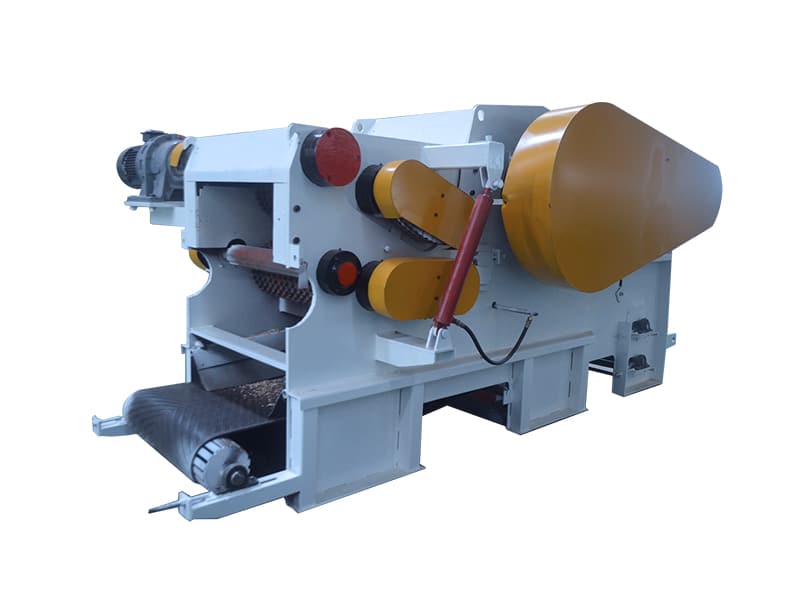

Small wood chippers play a vital role in the initial stages of biomass pellet production. These machines are designed to break down larger pieces of wood into smaller chips or pieces. The uniformity in chip size is essential for consistent pellet quality and efficient combustion. By reducing wood to a standardized size, the small wood chipper ensures that the subsequent processes, such as drying and pelletizing, are more effective.

Benefits of Small Wood Chippers

- Size Uniformity: Small wood chippers ensure that the wood chips produced are of consistent size. This uniformity leads to even drying and compression, resulting in uniformly dense pellets.

- Increased Efficiency: Chipping wood before pelletization enhances the overall efficiency of the process. Uniform chips allow for better airflow during drying, reducing moisture content effectively.

- Reduced Energy Consumption: Smaller wood chips require less energy during the drying process, as they have a larger surface area-to-volume ratio. This results in quicker and more energy-efficient drying.

- Enhanced Combustion: Uniformly sized wood chips facilitate smoother combustion in pellet stoves and boilers. The consistent size allows for controlled and efficient burning, minimizing waste and emissions.

- Equipment Longevity: By pre-processing the wood, small wood chippers help protect downstream equipment like pellet mills from damage caused by oversized or irregularly shaped pieces.

- Cost Savings: The use of small wood chippers contributes to cost savings in the long run. Efficient drying and combustion processes translate to reduced fuel consumption and maintenance expenses.

Considerations When Choosing a Small Wood Chipper

- Capacity: Select a chipper that matches the required throughput for your biomass pellet production.

- Size of Chips: Different pelletizing systems require specific chip sizes. Ensure the chipper can produce chips that align with your pelletizer’s requirements.

- Durability: Look for well-built machines that can withstand the demands of continuous operation.

- Maintenance: Opt for chipper models with accessible parts, making maintenance and cleaning more convenient.

- Safety Features: Prioritize chippers with safety mechanisms to prevent accidents during operation.

Conclusion

In the realm of sustainable energy solutions, biomass pellets stand out as a renewable resource with vast potential. Small wood chippers play a crucial role in shaping the journey from raw wood to these energy-dense pellets. Their ability to transform bulky wood into uniform chips contributes to efficient drying, pelletizing, and combustion processes. By understanding the significance of small wood chippers in biomass pellet production, we pave the way for greener energy alternatives and a more sustainable future.