The feed pellet machine is widely used in agriculture, aquaculture, and aquaculture. It can make pellet feed for chicken, duck, goose, cow, pig, sheep, rabbit, fish, shrimp, dog and cat.

Every livestock owner knows the importance of customized nutrition for animal health. With our feed pellet machine you become the master of your animal’s diet. Easily adjust ingredients, ratios and particle sizes to create individual feed formulations. No matter what livestock you raise, our machines can provide tailored nutrition to help your livestock succeed.

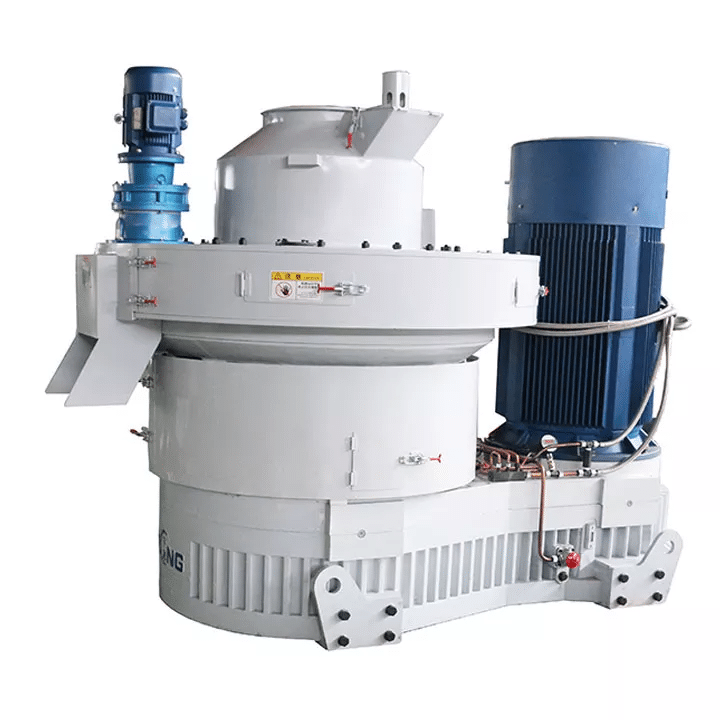

Animal feed pellet mill for sale

We offer a wide range of animal feed pellet machines to suit a variety of farming needs and scales. Our goal is to provide high-quality feed processing equipment.

Generally, animal feed pellet mill can be divided into two types: flat die pellet machine and ring die pellet machine. Be aware of these things: The efficiency of flat die mill is low, so they are suitable for small-scale production; Ring die mill have a high production efficiency and are suitable for mass production. Therefore, when we buy a pellet machine, we should choose the one that fits our needs.If you don’t know which machine to buy, please contact us. According to your business needs, our sales staff will find you a suitable solution. Click here >>

Why Choose Our feed pellet machines?

- Versatility:Our pellet machines process poultry, livestock, aquaculture, and other types of animal feed. Whether you need equipment to produce high-protein or high-fiber feeds, we can provide it.

- High Production Efficiency: Using advanced processes and technologies, the equipment is highly efficient and productive.

- Reliability and Durability: The equipment is built with high-quality materials for long-term durability and stability.

- Easy Maintenance: The equipment is easy to maintain and clean because of its simple structure.

What raw materials are suitable for processing?

The raw materials for a feed pellet machine generally include the following categories:

- Cereal-based materials: These include various grains such as corn, wheat, soybeans, rice, oats, etc. These grains are typically the main sources of energy and carbohydrates in the feed.

- Protein sources: These include legumes (soybeans, peanuts, etc.), fish meal, meat and bone meal, etc. Protein is an essential nutrient for animal growth and metabolism.

- Fats and oils: These can come from plant oils (such as soybean oil, palm oil), animal fats, serving as sources of energy and carriers for fat-soluble vitamins.

- Fiber sources: Examples include silage, straw, wood shavings, etc. These can aid in promoting digestive system health and increasing the fiber content of the feed.

- Minerals and vitamins: Feed usually requires the addition of minerals (such as calcium, phosphorus, iron, etc.) and vitamins to meet the animals’ micronutrient needs.

- Additives: These include antibiotics, enzyme preparations, probiotics, etc., used to enhance the nutritional value and digestibility of the feed, while also contributing to the animals’ health and growth.

- Other byproducts: Feed production often utilizes agricultural byproducts and processing residues, such as rice bran, wheat bran, etc., to reduce waste and production costs.

How are feed pellets processed?

The processing of feed pellets involves several key steps. First, raw materials like grains and protein sources are collected and stored. These materials are then ground to a consistent particle size for better mixing. Next, the ground ingredients are thoroughly mixed to create a uniform blend. This mixture is conditioned with heat and moisture to enhance its binding properties. The conditioned mixture is then pressed through a die in a pellet mill, forming compact pellets. After pellet formation, they are cooled to harden and stabilize them. The Cooled pellets are sieved to remove fines and defects and then packaged for distribution and animal consumption.

Build your own feed pellet plant

To establish a feed pellet factory, you’ll need a complete pellet machine production line. This line encompasses various essential components to ensure efficient feed pellet production. Some key elements include:

- Pellet Machine: It is the core of the production line, transforming raw materials into feed pellets.

- Hammer Mill: This equipment grinds raw materials into the appropriate particle size for pelletization.

- Conveyor System: To move materials between different stages of the production process.

- Pellet Cooler: After pelletization, the pellets are cooled to remove excess moisture and enhance shelf stability.

- Pellet Screener: This device removes fines and unevenly sized pellets, ensuring a consistent final product.

- Packaging Machine: The final step involves packaging the pellets for distribution and sale.

Using these components, your feed pellet factory will produce high-quality feed pellets efficiently. Choosing our pellet machine production line is not only a commitment to product quality, but also an investment in your success. Contact us now and let’s break new ground in production together! Click here >>