Table of Contents

Introduction to Biomass Pellet Production Line

The biomass pellet fuel production line is a type of biomass energy utilization technology. It uses wood, sawdust, straw, rice straw, legume stems, and other biomass as raw materials. It undergoes physical processes such as crushing, sorting, and extrusion. Various molded fuels can save energy. They also have good economic and social benefits. They are ideal choices to replace fossil energy fuels.

In this article, we will introduce the biomass pellet production line technology in detail.

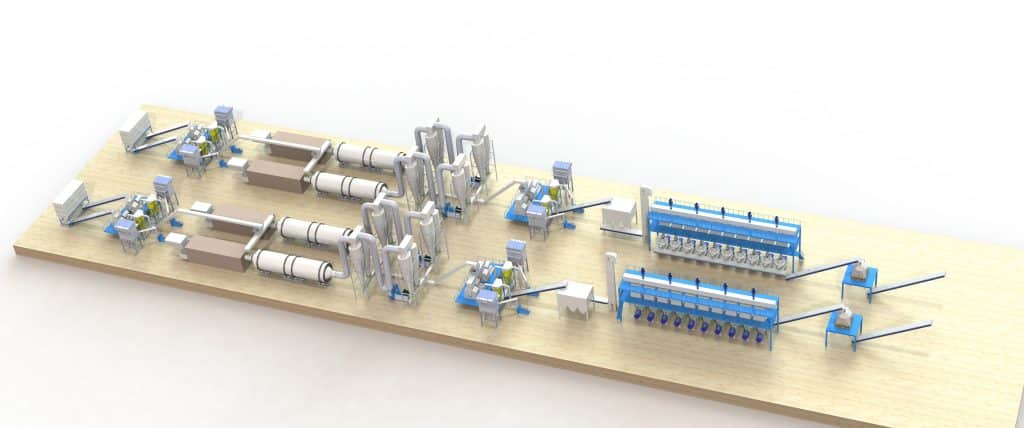

What are the Main Components of the Pellet Line?

First, let’s summarize the main components of the biomass pellet fuel production line.

- Raw material processing part: including raw material cleaning, crushing, screening and other equipment.

- Drying part: including air flow dryer, rotating drum dryer and other equipment.

- Compression part: including flat mode granulator, ring mode granulator and other equipment.

- Cooling part: including cooler, belt conveyor and other equipment.

- Screening part: including screening machines, granulators and other equipment.

- Packaging part: including packaging machines, measuring devices and other equipment.

- Exhaust gas treatment part: including dust collector, exhaust gas processor and other equipment.

What is the Main Process Flow of Pellet Manufacturing?

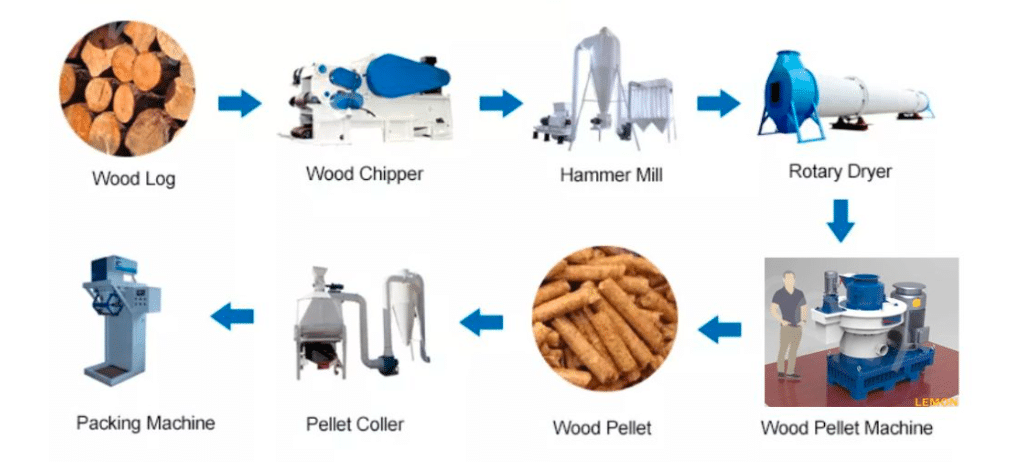

So how are biomass pellets made? Next, we will focus on introducing the main process flow of particles.

1. Collect raw materials

The raw materials of biomass pellets usually include wood, straw, reeds, peanut shells, corn straw, rice straw, and others. Choose based on local resources and market demand. At the same time, the raw materials of biomass pellets should have the following characteristics:

- 1. Low moisture content: The moisture content in raw materials cannot exceed 10%.

- 2. Low ash content: ash content should be less than 1%.

- 3. Low sulfur content: sulfur content should be less than 0.05%.

- 5. Low impurity content: such as stones, metals, etc.

- 4. High density: The greater the density of raw materials, the smaller the energy consumption during the production process and the higher the production efficiency.

The raw material collection process should ensure the diversity of raw material sources. It should also reduce reliance on a single source. At the same time, consider environmental protection during the collection process. This avoids environmental pollution.

2. Raw material pretreatment

Raw material preprocessing mainly includes slicing, crushing, drying, sorting and other links.

Slice:

Use a wood chipper to cut biomass feedstock (large pieces of wood) into pieces approximately 2.5 cm (0.98 in) or smaller. This prepares the feedstock for crushing.

Broken:

A hammer mill is used to crush and chop the raw material into a very small powder. This usually reduces the size of the raw material to 5 mm (0.20 in) to make it easier to process.

dry:

Put the raw materials into the biomass drum dryer to evaporate the water in the raw materials and improve the dryness of the raw materials. The dried raw materials have good fluidity, Facilitates subsequent compression and granulation. It also prevents the granules from becoming moldy during storage.

sorting:

The main purpose is to remove impurities in the raw materials, such as stones, metals, etc., to ensure the quality of the produced particles.

3. Pellets making production

In the compression part, the raw materials enter the flat plate compressor or the ring mode compressor. Under high temperature and high pressure, the raw materials are affected by extrusion and friction. They undergo thermoplastic deformation to form granular materials. The shape and size of the particles can be adjusted according to different standards.

4. Drying and cooling

The pressed biomass pellets need to be cooled. Cooling rapidly lowers particle temperatures from a high state. This reduces particle humidity and improves particle hardness and stability. The cooling process usually uses coolers and fans. They allow the particles to reach the ideal humidity and temperature through proper cooling and wind discharge.

5. Pellets packaging

Cooled pellets require packaging to prevent contamination or damage during transportation and storage. Packaging materials should be environmentally friendly and recyclable. For example, paper bags and woven bags.

Pellet Production line case at customer site Video

Below is a video of our customers processing pellets on-site. It can help you better understand how our equipment works.

Is there investment value in a pellet production line?

So is this equipment suitable for investment? The biomass pellet production line is a very promising investment project. As environmental awareness increases, more companies are paying attention to biomass pellets. They are a green energy source. In the future market, the demand for biomass pellet production lines will increase. The investment cost of the biomass pellet production line is relatively low. The payback period is short, making it a very cost-effective investment option.

What are the advantages of a pellet line?

The biomass pellet production line has an advantage. It can use biomass resources such as agricultural and forestry wastes for production. This effectively solves the problems of resource waste and environmental pollution. Biomass pellets are a clean and renewable energy source. They are widely used in industrial boilers, home heating, and power generation. They are also used in other fields. The biomass pellet production line can promote rural economic development. It can also improve the efficiency of biomass resource use and raise farmers’ income.

Why buy our machine?

Our company insists on technological innovation to succeed in the competitive market. We invest a lot of money in R&D and upgrades. Our equipment has won wide recognition in the market.

Key features of our biomass production lines include:

- Suitable for a variety of materials, such as sawdust, straw, etc.

- Automated control system, intelligent monitoring, high cost performance.

- High energy efficiency and sustainable production.

- Meet flexible production and customization needs.

- Easy maintenance, stable and reliable.

- Pellet production line process flow

- The particle quality is stable and meets environmental protection standards.

- Environmentally friendly emissions and reduced pollution.