Are you looking for a machine suitable for home production of biomass pellets? Then please choose this small wood pellet mill. The machine is very efficient and is ideal for production on a small scale. It will meet your needs and bring you wealth. In the following content, you will learn more about this machine.

What is a small wood pellet mill?

Firstly, a brief explanation of the machine. This pellet mill is a machine used to make biomass pellets from various types of raw materials. It is commonly used in the production of wood pellets, and animal feed pellets. This pellet machine is simple, easy to operate, low-cost, and suitable for small-scale production.

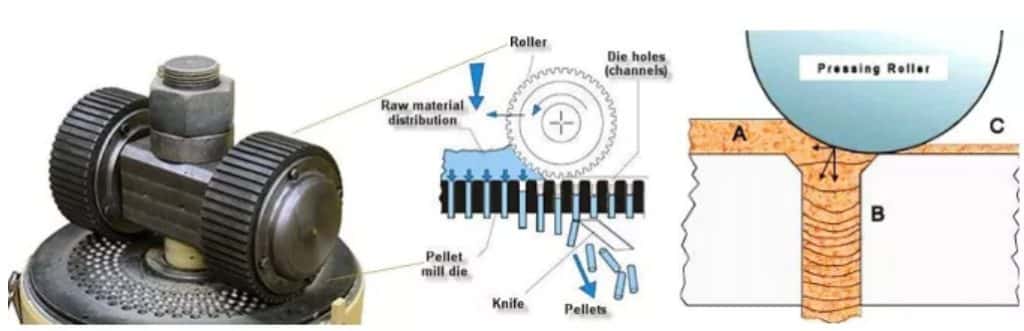

As its name implies, a flat die pellet mill uses flat dies to make pellets. This flat die pellet machine works based on the principles of extrusion and molding. The main components include a flat die (called a “flat die”) and a rotating press roller. The raw material is squeezed into the hole of the flat die by the roller to form a granular product. Die sizes and configurations vary to produce pellets with different diameters and lengths. The working principle of the flat die pellet machine can be found in this article. >> How does a pellet mill work

Small wood pellet machine for sale

Are you looking for a feed pellet machine for sale? Then this flat die pellet machine is definitely suitable for you. It is specifically designed to produce wood pellets and feed pellets. Compared to other machines, this one is very cost-effective. There are a variety of models to choose from according to your needs. Below is a table that shows the parameters of each machine model.

| Model | Capacity (kg/h) | Power (kw) | Weight(kg) | Dimension (mm) |

| LM210 | 80-100 | 7.5 | 280 | 1100*400*980 |

| LM250 | 150-200 | 15 | 400 | 1120*440*1060 |

| LM300 | 200-300 | 22 | 800 | 1280*560*1220 |

| LM350 | 350-400 | 30 | 900 | 1300*530*1220 |

| LM400 | 400-600 | 37 | 1000 | 1390*650*1290 |

| LM450 | 650-800 | 45 | 1500 | 1620*700*1600 |

| LM550 | 1000-1500 | 55 | 1800 | 1700*700*1600 |

Getting a quote or more information is easy. Contact us if you have any questions. >> Click here

What industry does this machine suit?

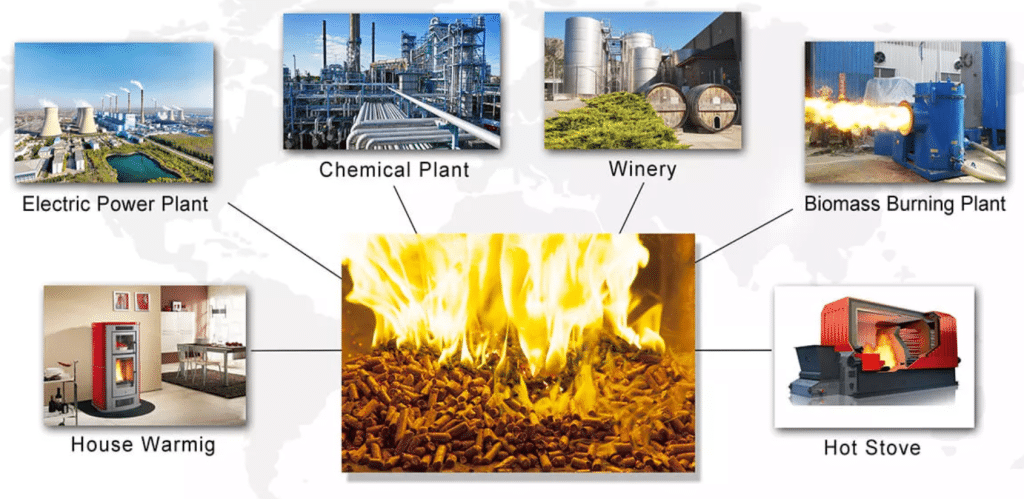

So in what industry can this machine achieve economic benefits? Pellet mills are used primarily to produce animal feed pellets, wood pellets, etc. Pellet mill plants or individuals have achieved great economic success in these industries. Here are the main application scenarios of flat die pellet mills:

- Animal Feed Production: To produce livestock, poultry, and other animal feed pellets.

- Biomass Energy Production: To convert biomass waste, such as wood chips, sawdust, and straw, into biomass fuel pellets. These pellets can be used for heating, power generation, and industrial purposes.

- Organic Fertilizer Production: Pellet mills are also used to manufacture organic fertilizers from organic wastes.

- Woodworking Waste Utilization: The pellet mill can convert wood shavings and sawdust into valuable wood pellets.

Flat die pellet mill parts

Would you like to learn more about this machine’s structure? The following is a description of how the machine is structured。

- Hopper — The hopper is the top part of the pellet machine, where the raw materials are loaded into the machine. As a reservoir, it holds the biomass feedstock before it goes into the pelletizer.

- Pelletizing Chamber — The pelletizing chamber is the main working area of the pellet machine. Here, the pelletization process takes place using a flat die and rollers.

- Flat Die — the flat die is a horizontal circular disc with many small holes drilled through it. Pellets are formed by forcing raw materials through these holes under high pressure.

- Rollers — The rollers are usually mounted on top of the flat die and can move back and forth. As the die rotates, raw materials are pressed against the flat die, forcing them through the holes.

- Pellet Cutter — It is a blade or knife-like component located near the pellet outlet. After pellets are extruded from holes in the flat die, the pellet cutter trims them to the desired length.

- Discharge Chute — Once the pellets are cut to the appropriate length, they are discharged through a chute or outlet. Pellets are discharged into a collection container for further handling and storage.

- Motor — Flat die pellet machines are typically powered by an electric motor or a diesel engine. As a result of the motor, the flat dies and rollers are driven, which enables pelletization to take place.

- Control Panel Cabinet — The cabinet allows operators to adjust the pelletizing process, such as the feed rate or temperature.

- Lubrication circulation oil pump — The lubrication circulation oil pump is an essential component of a pelletizer machine. It keeps the equipment’s moving parts lubricated to reduce friction and wear. It extends the equipment’s lifespan and ensures efficient operation.

Flat die pellet mill working video

In this video, you can see a small wood pellet production line using a flat die pellet machine. Our customers have already made their first pot of gold using this production line.

Frequently Asked Questions

If you have any questions about the flat die pellet mill, you can find answers to some frequently asked questions below. Please contact us if you do not find your answer here.

What is the difference between ring die and flat die pellet mills?

Die Design and Structure:

- In a ring die pellet machine, the die is a cylindrical shape with multiple holes drilled through it.

- In a flat die pellet machine, the die is a flat plate with holes drilled into it.

Efficiency and Output:

- Ring die pellet machine tend to be more efficient and better suited to large-scale production.

- Flat die pellet machine are typically used for smaller-scale production

What is the most accurate pellet shape?

Pellet shapes are typically determined by the application. Cylindrical pellets are one of the most common shapes. They are easy to produce and handle, making them suitable for a wide range of applications.

What size are pellet mill die sizes?

Here are some general ranges of pellet mill die sizes:

- The diameter is usually 100mm to 400mm (approximately 4 inches to 16 inches).

- The number of holes in a die is usually between 5 and 30 depending on the size.