Sawdust pellets, also known as wood pellets, are a form of biomass fuel. The pellets are made by subjecting sawdust or wood waste to high pressure. The natural lignin in the raw material forms a binder, resulting in dense, cylindrical pellets.

advantages of sawdust pellets

Sawdust pellets have become a popular renewable energy source. They are especially popular for heating. They offer numerous advantages over traditional fuels, such as coal or oil. Firstly, they are considered a sustainable and environmentally friendly alternative. They are derived from a renewable resource—wood. Additionally, they have a lower carbon footprint. Burning wood pellets releases fewer greenhouse gas emissions than burning fossil fuels.

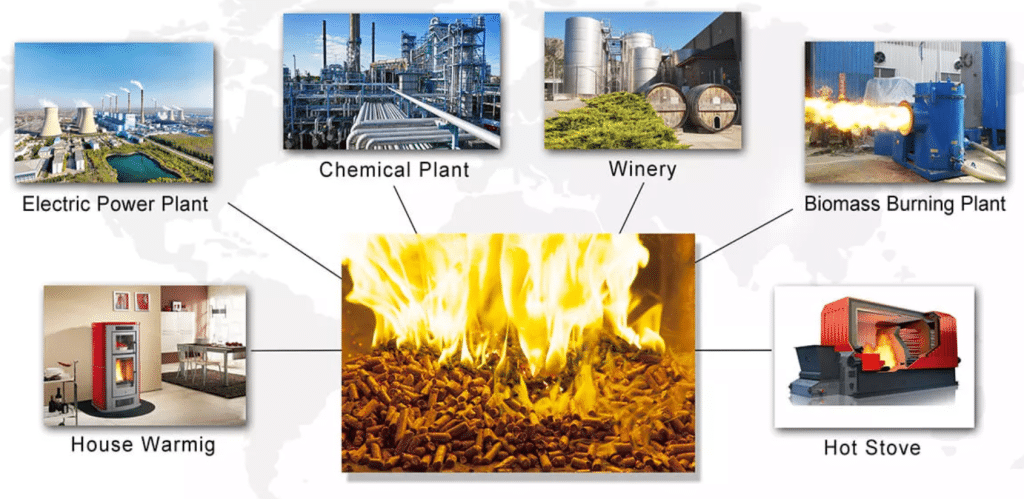

What are the uses of sawdust pellets?

Sawdust pellets have various uses across different industries and applications. Here are some common uses of sawdust pellets:

- Residential Heating: Sawdust pellets are commonly used as a source of heat in pellet stoves and pellet boilers for residential heating. These pellets provide consistent and efficient heat. They are a popular choice for homeowners looking for a renewable and sustainable heating option.

- Commercial and Industrial Heating: Sawdust pellets are also used in commercial and industrial settings for heating applications. They work in heating systems for schools, offices, factories, and other large-scale facilities. They provide an eco-friendly and cost-effective solution.

- Power Generation: Sawdust pellets are used in biomass power plants to generate electricity. These power plants burn sawdust pellets to produce steam, which drives turbines to generate electricity. This helps diversify the energy mix and reduce reliance on fossil fuels for power generation.

- Animal Bedding: Sawdust pellets can be used as bedding material for animals, such as horses, poultry, and livestock. The pellets provide a comfortable and absorbent bedding surface, helping to maintain cleanliness and hygiene in animal enclosures.

- Animal Feed: In some cases, sawdust pellets can be used as a component in animal feed. They may be mixed with other feed ingredients to provide additional fiber or as a supplementary energy source in animal diets.

- Cat Litter: Compressed sawdust pellets can be used as an eco-friendly alternative to traditional clay-based cat litter. The pellets offer good absorption properties and can be easily disposed of or composted.

It’s worth noting that the specific uses of sawdust pellets may vary. This depends on the region, availability, and local regulations.

What machine turns sawdust into pellets?

The Parts Of the Pellet Machine

The machine used to turn sawdust into pellets is called a pellet mill or pellet press. It is a specialized piece of equipment designed to compress and shape sawdust or wood shavings into uniform pellets.

A pellet mill typically consists of the following components:

- Feeding System: This system is responsible for feeding the sawdust or wood shavings into the pellet mill. It may include a hopper or conveyor belt to transport the raw material to the next stage.

- Conditioning System: The conditioning system may be present in some pellet mills, especially those used for large-scale production. It involves adding moisture to the sawdust to improve pellet formation and durability.

- Pelletizing Chamber: This is the main part of the pellet mill where the sawdust is compressed and shaped into pellets. Inside the pelletizing chamber, a die with small holes is mounted. The sawdust is forced through these holes under high pressure, resulting in the formation of cylindrical pellets.

- Roller and Die: The pellet mill is equipped with a set of rollers and a die. The rollers press the sawdust against the die, which has the desired pellet size and shape. The pressure applied by the rollers and the design of the die determines the density and characteristics of the resulting pellets.

- Cutting System: Some pellet mills have a cutting system integrated into the machine. This system cuts the continuous pellet mass into the desired pellet length as it exits the die.

It’s worth noting that pellet mills come in various sizes and capacities, ranging from small-scale models for home use to large industrial units for commercial production. The specific design and features may vary depending on the manufacturer and the intended scale of operation.

How are sawdust pellets made?

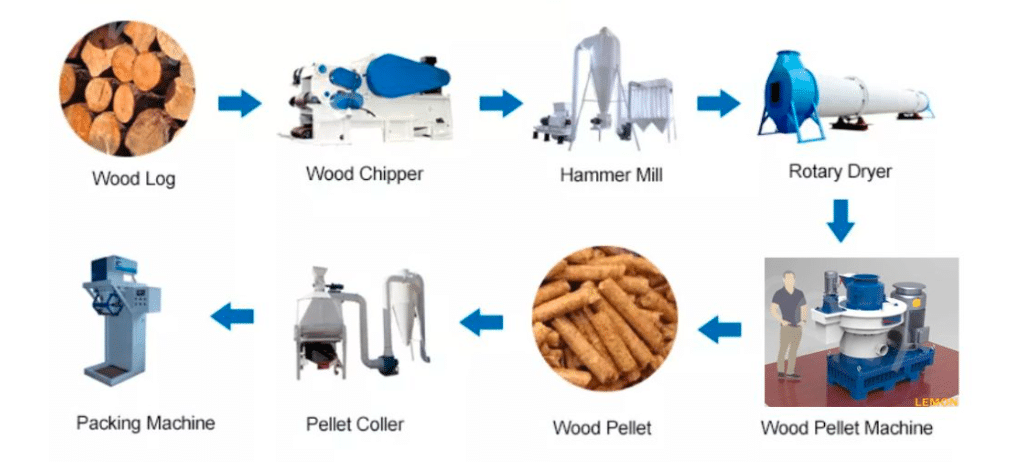

Sawdust pellets, also known as wood pellets, are made through a process that involves several steps. Here is a general overview of how sawdust pellets are made:

Raw Material Preparation

The first step involves collecting and preparing the sawdust or wood shavings that will be used to make the pellets. The raw material should be clean and free from contaminants such as stones, metals, or excessive moisture. Sawdust from sawmills, woodworking shops, or other wood processing operations is commonly used.

Drying

If the sawdust has a high moisture content, it needs to be dried before pelletization. Excess moisture can make pelletizing difficult and lead to poor pellet quality. The sawdust is typically dried in a rotary drum or flash dryer to reduce its moisture content to the optimal range, usually below 10%.

Grinding

In some cases, the dried sawdust may undergo a grinding or milling process to reduce its particle size. Grinding can improve the pelletization process by creating a more uniform feedstock and increasing the surface area for binding.

Pelletization

The dried and optionally ground sawdust is fed into a pellet mill or pellet press. The sawdust is compressed and shaped into pellets inside the pellet mill through high pressure and heat. The process involves the following steps: a.

Feeding:

The sawdust is introduced into the pellet mill through a feeder system, which can be a hopper or a conveyor belt.

Compression:

Inside the pellet mill, the sawdust is forced through small holes in a die by a set of rollers. The pressure exerted by the rollers compresses the sawdust, causing it to bind together and form pellets. The heat generated during compression helps soften the lignin in the wood, acting as a natural binder.

Cutting:

As the continuous pellet mass exits the die, it is cut into the desired pellet length by a cutting system integrated into the pellet mill. The pellets are then separated from the remaining biomass.

Cooling:

After pelletization, the hot pellets are typically cooled to reduce their temperature and moisture content. Cooling can be done using a pellet cooler, which uses ambient air or forced air to remove heat and moisture from the pellets. This step helps stabilize the pellets and improves their durability.

Sieving and Packaging:

The cooled pellets may go through a sieving process to remove fines or oversized pellets, ensuring uniform size distribution. Once sieved, the pellets are ready for packaging. They can be packed in bags, stored in bulk containers, or loaded into delivery trucks for transport.

How much sawdust makes a ton of pellets?

The amount of sawdust needed to make a ton of pellets can vary. This depends on factors such as sawdust density and moisture content. It also depends on pellet mill efficiency and desired pellet characteristics.

However, as a general guideline, it is estimated that approximately 1 ton of wood pellets can be produced from 2-2.5 tons of raw sawdust.

The moisture content of the sawdust can influence the conversion rate of sawdust to pellets. If the sawdust has a higher moisture content, it will require more energy and time during pelletization. This will result in lower pellet yield. It is important to ensure that the sawdust is properly dried to the optimal moisture level before pellet production. Therefore,

It’s worth noting that pellet production is not 100% efficient, and some loss may occur during the process due to factors such as fines generation or machine inefficiencies. Additionally, the pellet quality and density requirements may impact the final yield.

The specific conversion rate of sawdust to pellets may vary depending on the equipment used, the pellet mill settings, and the characteristics of the sawdust being used. It is advisable to consult the pellet mill manufacturer or conduct small-scale trials to determine the precise conversion rate for a given setup and sawdust material.

Sawdust pellet machine for sale

Sawdust Pellet Machine Line Working Video

Also Read: What are The Uses Of Biomass Dryer?