Are you ready to embrace a greener, cleaner energy future? Our biomass ring die pellet mill is your best choice. It’s a simple yet powerful innovation that is changing the way we sustainably produce energy.

what is a biomass pellet machine?

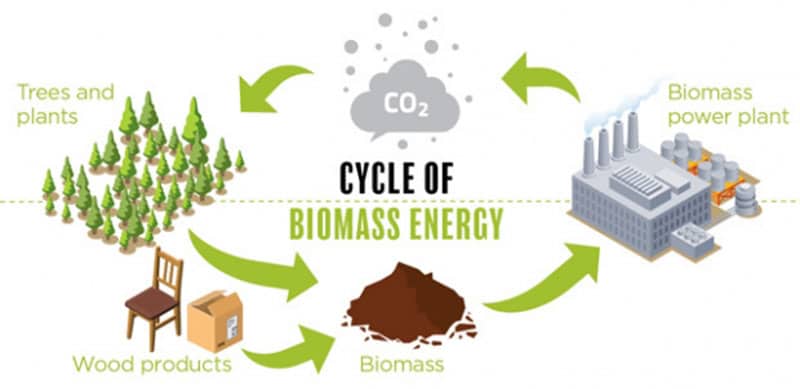

A biomass pellet mill is a machine used to compress biomass and make pellets or briquettes. There are many biomass sources, such as wood, crop residue, agricultural waste, and animal manure, among others. These pellets are like tiny energy bombs – they burn efficiently, giving you heat for your home or energy for your business.

The pelletizer machine is widely used in power stations, wood factories, feed factories, toy factories, and chemistry factories. You can read about the pellet machine’s working principle here. >> How a pellet mill works

In addition, Biomass pelletizer machines can be classified into flat die pellet machines and ring die pellet machines. A ring die pellet mill is generally larger and more efficient than a flat die pellet mill, making it suitable for high-volume production. These two types of machines differ in mold structure and operational principles. For a detailed introduction to the two machines, please read this article >> The difference between flat die and ring die pelleting machines.

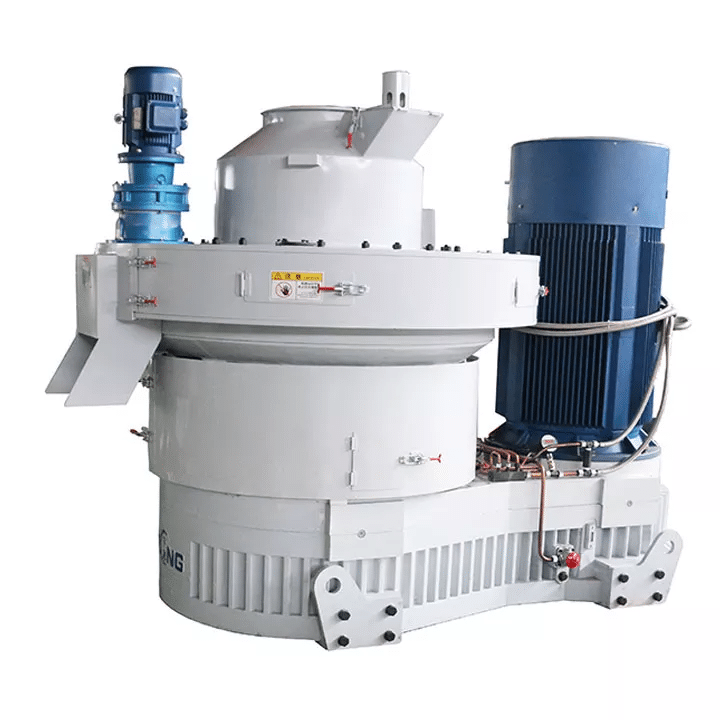

Ring die pellet mill for sale

If you want to buy a ring die pellet machine or create a pellets production line, please choose Jinan Lemeng manufacturer. As a trailblazing biomass pellet mill supplier, Jinan Lemeng shapes the future of biomass transformation. Our machines are meticulously designed, engineered, and crafted to deliver unparalleled performance.

There are many models of machines that you can choose from in our range:

| Model | Power(KW) | Capacity(T/H) | Weight(T) | Dimension(MM) |

| LM560 | 90/110/132 | 1.5-2 | 5 | 2300*1500*1800 |

| LM700 | 160 | 2-3 | 8 | 2600*1600*2100 |

| LM850 | 258 | 3-4 | 9.5 | 3000*1800*2300 |

If you do not know what model to choose, please contact our sales representatives for help. >> Click here

Why choose lemon Pellet machine?

Here are some outstanding features and advantages of our highly efficient pellet machine:

- Outstanding Production Capacity —— We use advanced compression technology and engineering techniques to produce biomass pellets. Its high capacity makes it an ideal choice for industrial production.

- Precision Mold Design —— We have conducted in-depth research and optimization in mold design to ensure the uniformity and stability of pellets. By doing this, pellets will have consistent size and density, improving combustion efficiency.

- Wide Range of Applicable Raw Materials —— Whether wood chips, straw, peanut shells, or any other biomass material, our machine efficiently converts them.

- Low cost and low energy consumption —— We designed our pelleting mill to cut energy consumption to reduce production costs.

- Comprehensive After-Sales Service —— Our company offers comprehensive after-sales support, including equipment installation, commissioning, and training. Our goal is to ensure that customers are confident in the equipment and have an excellent user experience.

How to make wood pellets?

Are you interested in how wood pellets are made? First, let us watch a video, take a tour of the pellet mill plant, and see how the pellets are made.

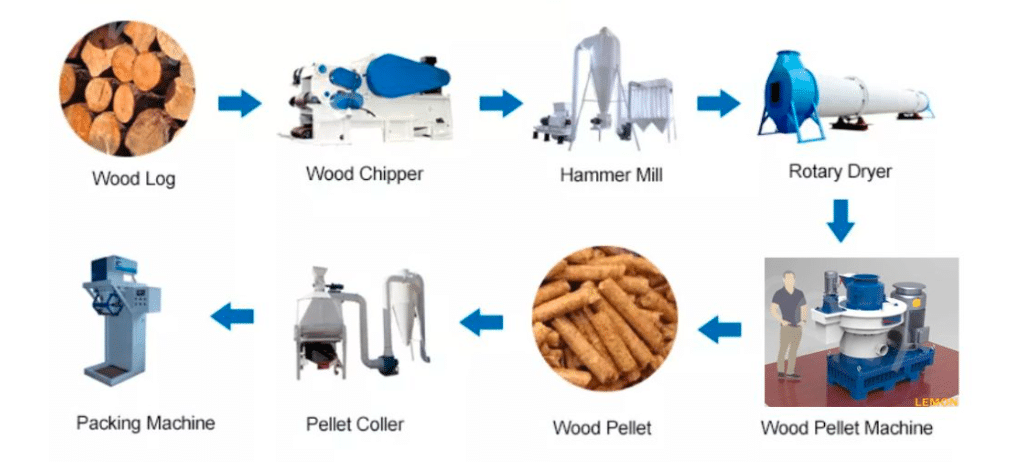

Then, Here is a picture showing how pellets are produced. Please review the picture after watching the video.

As a side note, here is a quick look at the processes that are involved :

- Material Preparation: In this process, you will need a wood chipper and a hammer mill. Materials are chipped, ground, or shredded to reduce their size. This ensures that the materials are of uniform size and suitable for pelletization.

- Drying: Biomass materials usually have moisture content, which must be reduced before pelletization. Excess moisture can negatively impact the quality and combustion efficiency of the pellets. Drying the materials also makes them easier to process. In this process, you will need a rotary dryer.

- Pelletization: The prepared raw materials are fed into the pellet mill, which is the core machine of the production line. The extruded material emerges from the die in the form of cylindrical pellets.

- Cooling: The freshly extruded pellets are hot and soft. It is important to cool them to make them more durable.

- Packaging: The cooled pellets are ready for packaging. They can be bagged, boxed, or stored in bulk for further use or distribution.

Now I believe you will have a clearer understanding of the pellet production process. If you wish to establish your own pellet mill plant, then you should introduce our production line. Check out this article for more information. >> (Lemon Pellets Production Line). If you want to get a quote please Contact Us.

Frequently Asked Questions

If you have any questions about the ring die pellet mill, you can find answers to some frequently asked questions below.

how are wood pellets made?

Please refer to this article >> How to make wood pellets?

Can all pellet mills make wood pellets?

No. Many pellet mills are designed for making animal feed pellets.

Where can I find a wood pellet machine?

You can visit our website:www.lemonmach.com

Can I make wood pellets in my home? What should I do first?

YES. you can make wood pellets at home. The first step is to buy a pellet making machine from us, and we will provide comprehensive service support.

Please contact us if you do not find your answer here.